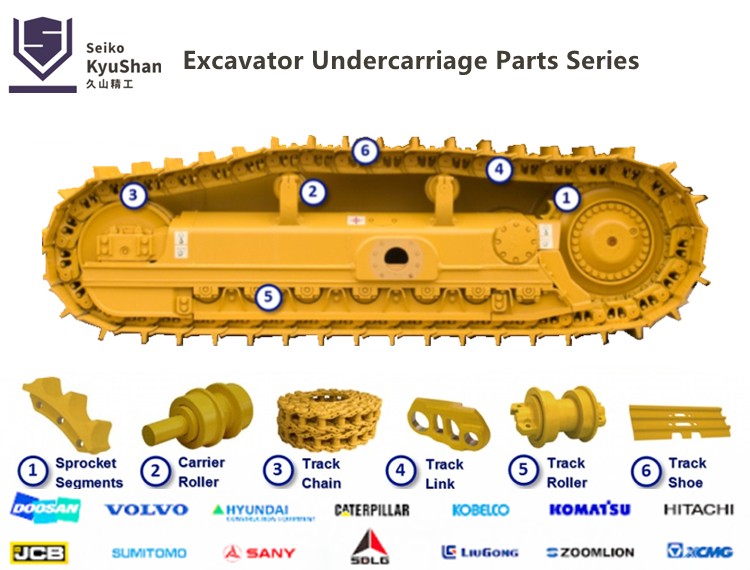

Increase Productivity With Undercarriage Parts and Its Uses

From track shoes to gears and idlers, undercarriage components play an important function in the performance and durability of devices. komatsu undercarriage parts. Allow's check out how services can harness the power of undercarriage components to enhance their procedures and drive success in an affordable market.

Importance of Undercarriage Parts

Regular maintenance and prompt replacement of undercarriage components are vital to avoid expensive downtime and take full advantage of productivity. Damaged undercarriage parts can result in minimized grip, raised fuel intake, and accelerated wear on other parts of the machinery. By purchasing top quality undercarriage components and adhering to a stringent upkeep schedule, drivers can enhance the efficiency of their heavy machinery and prolong its solution life.

Common Kinds Of Undercarriage Parts

Important parts necessary for the efficient procedure of heavy equipment, undercarriage parts play an essential duty in making sure optimal efficiency and longevity of the tools. Some common kinds of undercarriage parts consist of track chains, track footwear, rollers, idlers, gears, and track structures. Comprehending the feature and significance of these usual undercarriage components is important for preserving heavy equipment in optimum functioning condition, minimizing downtime, and maximizing performance on work sites.

Advantages of Regular Upkeep

Enhancing functional efficiency and extending tools life-span, routine maintenance of undercarriage parts is essential for making best use of hefty machinery efficiency. By adhering to an organized upkeep timetable, operators can prevent costly break downs and lessen downtime. Regular evaluations and servicing of undercarriage components such as tracks, idlers, rollers, and gears not only make certain smooth procedure yet additionally add to total security on job sites.

Enhancing Equipment Performance

Additionally, picking the ideal undercarriage parts for particular operating problems is important. When selecting undercarriage parts, variables such as the type of terrain, workload, and environmental problems need to be taken right into consideration. Utilizing premium components that are created to hold up against the needs of the work can boost overall equipment performance and long life.

In addition, maintaining undercarriage components clean and well-lubricated is crucial for smooth procedure. Dust, debris, and absence of lubrication can trigger premature deterioration on components, leading to reduced efficiency and possible failures. Routine cleaning and lubrication routines can assist prevent these issues and make certain regular devices performance.

Cost-Effective Solutions for Companies

To optimize undercarriage components successfully and guarantee long-term tools performance, companies should prioritize cost-efficient options that align with their functional requirements and budget restraints. Purchasing high-quality undercarriage components can result in substantial cost savings in the future by reducing downtime, upkeep prices, and the risk of unanticipated equipment failings. One cost-effective solution for businesses is to carry out an aggressive maintenance routine that includes regular inspections, lubrication, and prompt replacement of damaged undercarriage components. By determining and attending to prospective concerns early, services can you could look here protect against pricey repair services and extend the life-span of their equipment.

An additional cost-effective technique is to resource undercarriage components from trusted vendors that supply an equilibrium between quality and cost. These providers commonly give affordable prices, guarantee alternatives, and quickened shipping services, assisting companies decrease procurement costs and minimize equipment downtime. Additionally, companies can check out alternative undercarriage parts such as aftermarket parts that meet sector standards and specifications at a reduced price than OEM components. By very carefully examining their options and partnering with dependable distributors, businesses can effectively handle their undercarriage component costs without compromising on efficiency or integrity.

Verdict

In final thought, undercarriage components play a vital duty in enhancing devices efficiency and performance. It is clear that undercarriage parts are vital parts for businesses looking to improve productivity and preserve their devices in ideal problem.

From track footwear to gears and idlers, undercarriage components play a vital role in the performance and durability of equipment.The relevance of undercarriage components in hefty equipment can not be overemphasized, as they are important parts that considerably affect the general efficiency and durability of the devices.Vital components vital for the effective operation of heavy machinery, undercarriage components play an essential role in making sure ideal performance and longevity of the tools.Enhancing functional important site performance and lengthening tools life-span, routine upkeep of undercarriage parts is crucial for maximizing hefty equipment performance. Furthermore, organizations can explore different undercarriage parts such as aftermarket elements that fulfill industry criteria and requirements at a reduced cost than OEM components.